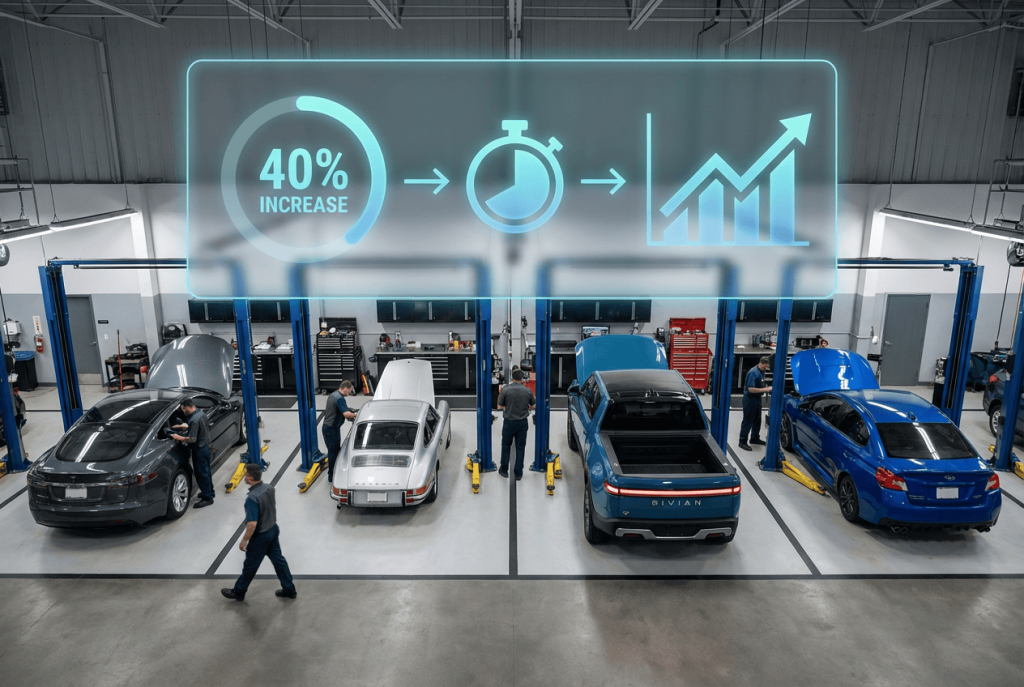

The Operational Blueprint That Increased Bay Efficiency by 40% Without Hiring More Staff

You’ve probably thought about hiring another technician or service advisor to handle the workload—but what if the problem isn’t too few people, it’s too much wasted time?

Most auto repair shops operate at 50-60% efficiency. Your technicians spend half their day on non-billable activities: searching for tools, waiting for parts, clarifying work orders, and dealing with communication gaps. Adding more staff just means more people operating inefficiently. The shops running at 80-90% efficiency aren’t working harder—they’ve eliminated the friction that eats everyone else’s productivity.

By the end of this article, you’ll understand which operational changes drive the biggest efficiency gains and how to implement them without disrupting your current workflow.

Contents:

How AI Receptionists and Online Booking Increase Capacity Without New Hires

The first thing we suggest auto repair shop owners do is implement a 24/7 AI receptionist combined with online booking, because it’s one of the services we offer our paying clients at Element DMA, and we see its impact firsthand on creating capacity without additional staffing costs.

Here’s what most shop owners don’t realize: your service advisors spend 30-40% of their day on phone calls—booking appointments, answering basic questions, providing status updates, and returning missed calls. This constant interruption prevents them from focusing on higher-value activities like selling additional services, processing checkout payments, and building customer relationships.

An AI receptionist handles routine calls, books appointments, answers common questions, and captures customer information 24/7 without pulling your service advisors away from revenue-generating activities. Combined with online booking that lets customers schedule themselves, this creates massive efficiency gains. Your existing staff can suddenly handle 40% more customer volume without working longer hours—they’re just focused on activities that actually drive revenue instead of answering repetitive questions.

The efficiency improvement compounds throughout your operation. When service advisors aren’t constantly interrupted, they complete tasks faster. When customers can book online during lunch breaks or after hours, your appointment calendar fills without phone time. When the AI receptionist provides consistent information to every caller, you eliminate the back-and-forth that wastes time.

Whenever we work with an auto repair shop at Element DMA, we also provide analytics that identify scheduling inefficiencies—showing exactly where bottlenecks occur and which time slots remain underutilized so you can optimize bay assignments.

The Communication System That Eliminates Productivity Loss

Beyond handling customer calls efficiently, digital work orders accessible on tablets eliminate 90% of communication-related time waste.

Paper work orders create transcription errors. Service advisors’ handwriting gets misread. Technicians walk to the front desk to ask questions. Customers call asking for status updates that interrupt advisors mid-conversation. All of this back-and-forth consumes hours that could be spent turning wrenches.

Digital work orders show complete job details including customer concerns, approved services, parts needed, and special instructions. When technicians update job status digitally, service advisors can answer customer questions without leaving their desk. Two-way texting lets advisors send photos and updates to customers without phone calls.

Three More Process Changes That Boost Bay Productivity

Parts Pre-Staging: Order and receive parts the day before scheduled appointments. Technicians start jobs with everything they need already in the bay instead of stopping mid-job to order missing parts. This single change can increase billable hours by 15-20%.

Bay Assignment Strategy: Assign specific types of work to specific bays with tools and equipment pre-positioned. One bay for alignments, one for diagnostics, one for general service. Technicians waste less time moving between bays and know exactly where everything is located.

Standardized Procedures for Common Services: Create written procedures for your ten most common repairs. New technicians get consistent training. Experienced technicians don’t waste time deciding approach. Parts lists ensure everything needed is ordered upfront.

What You Can Do Right Now

- Calculate how many hours per day service advisors spend on phone calls and routine inquiries

- Implement digital work order system accessible on mobile devices for real-time updates

- Create parts ordering process that stages components before appointments begin

- Track actual completion times for common services to improve scheduling accuracy

- You can also contact our team at Element DMA to see how we can bring your shop 100+ qualified calls per month and help your shop rank in the top 3 local search results

To Summarize…

The best ways for your shop to increase bay efficiency without hiring more staff is to implement AI receptionists and online booking that handle routine customer interactions, use digital work orders that eliminate communication gaps, and pre-stage parts before appointments—including working with Element DMA to automate customer communication and provide analytics that identify scheduling inefficiencies.

All the auto repair shops that work with us at Element DMA benefit from 24/7 AI receptionists that handle booking and inquiries without additional staff, online booking that reduces coordinator workload, and analytics that identify scheduling inefficiencies. Once you implement these operational improvements, you create capacity to grow revenue without proportionally increasing expenses.

With a background in psychology, Valeriu has worked in sales and marketing for 8+ years, and learned through experience that the best way to do business is to serve clients well, and solve their problems. He has joined Element DMA in September of 2025, attracted by the honest nature of the work and attitude of auto & truck repair shops. In this role, he helps shop owners across the U.S. see the ROI of properly done advertising, and the growth this brings to their shops, regardless of niche or state.